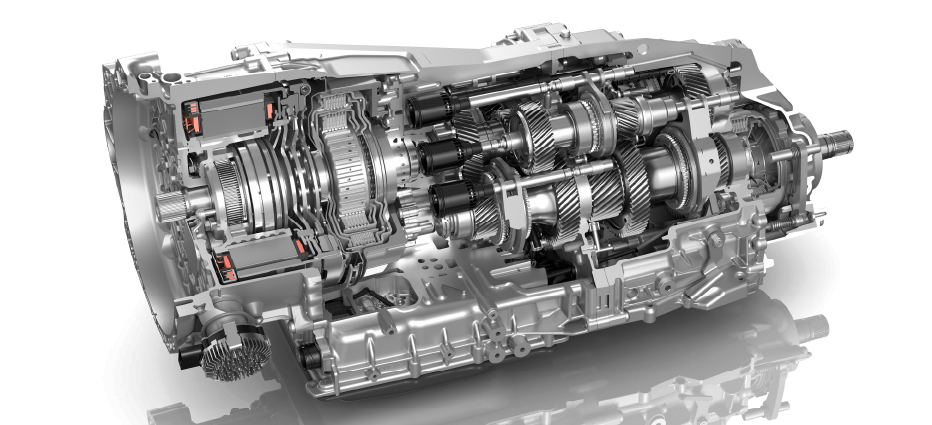

With an all-new 8-speed dual clutch transmission (8DT) as a basis, ZF and Porsche have collaborated to develop a modular hybrid transmission kit for sports vehicles, catering for current and future drive trends.

The new sports transmission, for rear-wheel and all-wheel drives, distinguishes itself from the competition with its incredibly rapid shift times, high levels of efficiency and flexibility. One major development goal was to make electric power an option for this transmission: Thanks to a new gear set design, it was possible to integrate a 100 kW hybrid module without increasing the length of the transmission, as compared to the current 7DT sports transmission. Another goal was an integrated all-wheel distribution option, driving the front axle in the most fuel-efficient manner possible using a hang-on clutch. Power loss in the basic transmission is reduced by up to 28 percent thanks to several factors: The gear spread, which at 11.17 is very high, an additional eighth gear and a demand-driven lubrication system and the optimized electronic transmission control unit (TCU) which was developed and produced independently by ZF. The new transmission is manufactured at the Brandenburg plant and volume production of vehicles featuring the 8DT began with the Porsche Panamera.

“In the new 8DT sports transmission, we combine blazing-fast shifts, a great level of efficiency and all-electric driving with the flexibility to integrate different variants within a tight installation space – without compromise,” says Dr. Jürgen Greiner, Head of Development for passenger car transmissions at ZF Friedrichshafen AG. Torque resistance, sporty performance, high levels of comfort and the efficiency of the new 8-speed dual clutch transmission surpass the current 7DT, even though its installation dimensions remain practically unchanged. Power loss can be reduced by up to 28 percent and the incredibly quick shift times were perfected even further. “The first six gears with their compact gradation optimizes acceleration to top speed. In contrast, the 7th and 8th gears are configured as overdrive, so they significantly decrease rpm and fuel consumption, even when not using electric power,” explains Greiner.

Modular hybrid transmission kit offers a huge range

The new 8-speed dual clutch transmission is available for front-longitudinal configuration in four different variants (standard, all-wheel drive, hybrid, all-wheel hybrid) in three torque classes, to a maximum of 1,000 Nm. The torque class is defined by the configuration variety of the dual-clutch modules, with the basic transmission and gear set always remaining the same. This is also true for the transmission hydraulics, shift system, parking lock and control unit, including software.

To make the 8DT basic transmission as small and compact as possible, a new gear set concept with two countershafts and one summation shaft was constructed. The fixed gears, which are all located on the transmission input shafts, can be used several times, resulting in less wheel levels, making the basic transmission significantly shorter in length. This was the only way to maintain the required length of the hybrid module and integrate it into the limited installation space. This gear set architecture offers another advantage. Based on the modular concept, it is not only suitable for front-longitudinal applications but will also be able to cater for other driveline configurations.

Zero local emissions – with integrated hybrid option

ZF has customized an already compact hybrid module for the optional variant of the new 8-speed dual clutch transmission. It includes a torsional damper, a separating clutch with actuators as well as the electric motor, and it can be integrated directly into the clutch bell housing. This does not alter the dimensions of the overall transmission but has considerable impact on its properties: With 100 kW peak output, 55 kW continuous power and 400 Nm torque, a vehicle can accelerate up to 140 km/h on pure electric power alone. With this technology, all other hybrid functions are also possible– from recuperation to boost mode.

Safer and more powerful: the integrated all-wheel distributor transmission

With the all-wheel drive variant of the 8DT, an integrated all-wheel distributor transmission transfers torque to the front axle gear as needed. The hang-on, all-wheel clutch is designed as a wet multidisk clutch. This multidisk package is operated under continuous slip. The clutch pressure varies depending on the torque required at the front axle reacting spontaneously to the given driving situation.

Intelligent mechanical systems: new electronic transmission control unit

The TCU and the transmission software for the 8DT were developed by ZF independently. The TCU is not integrated, but mounted externally. This prevents the electronics from limiting the transmission sump temperaturebelow150°C.

The TCU allows the 8DT highly dynamic functionality, as efficiently as possible, optimizing fuel consumption in conjunction with other vehicle systems. When operating in ECO mode, the control unit lowers the transmission pressure when driving conditions are suitable. This reduces power consumption without impairing comfort or performance. In stop-start mode, the combustion engine can be switched off from a speed of 10 km/h, while the vehicle is rolling to a stop. Furthermore, coasting with the engine off is possible even at high speeds.

The demand-driven lubrication system ensures that even more efficiency is attained in the 8DT. It does this by powering every sub-section of the transmission individually, depending on the driving situation. In terms of mechanics, the lubrication system consists of two pumps which are coupled via the hydraulic control unit. The software, Cool Oil Flow Management (COFM), which is stored on the transmission control unit, ensures the coordination and regulation of these complex processes. Depending on the driving conditions, it continuously determines the present volume flow requirement for all transmission components. Based on this, COFM sets the oil flow as needed and utilizes both pumps to supply the required amount. In addition to this, COFM determines the cooling requirements of the gearing for each gear, specifically, and constantly provides the required oil flow for each sub-section of the transmission engaged in power transmission at that point in time.