Viel Know-how unter der Haube: Panasonic Industry Filmkondensatoren als Bindeglied zwischen Wechsel- und Gleichstrom. Foto: Panasonic Industry

Viel Know-how unter der Haube: Panasonic Industry Filmkondensatoren als Bindeglied zwischen Wechsel- und Gleichstrom. Foto: Panasonic Industry

Whether in the kitchen or bathroom, in terms of hi-fi, consumer electronics and telecommunications, right up to the office or construction site: Panasonic has a number of high-quality electronic products on offer for almost every area of life. The long-established company has also been playing a leading role in all aspects of electromobility for some time, although the often very small but innovative components are often not as eye-catching as the well-known televisions, cameras or kitchen appliances. The components are hidden in electric and hybrid cars as well as in charging stations or the home wall box. Invisible from the outside, capacitors and relays from Panasonic Industry, for example, help to increase energy efficiency and safety and ultimately promote electromobility. We present selected components.

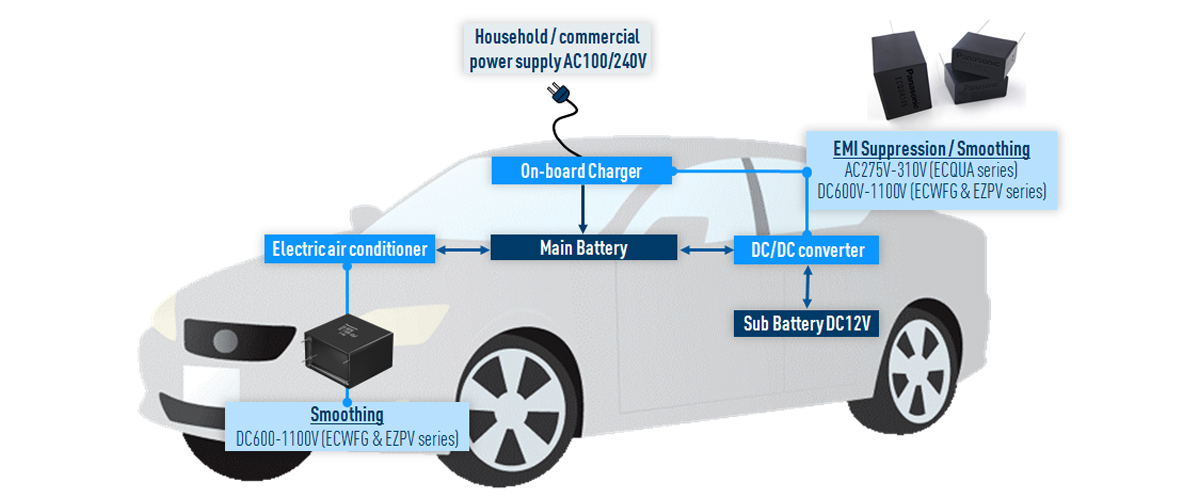

Components in the electric vehicle

Panasonic proved its foresight early on with the motor for an e-bike, which the company launched on the market back in 1979. Today, the Japanese electronics group, which has also been developing in Europe for Europe for a long time, is the market leader in numerous product areas for electric and hybrid vehicles for the private and commercial sectors, such as film capacitors. These are located between the engine and the battery and serve as a kind of buffer and optimal link between alternating current and direct current. As a result, the film capacitor maximizes the efficiency of the motor. Panasonic Industry supplies this small but essential component to leading manufacturers of electric and hybrid vehicles worldwide.

With over 40 percent global market share, Panasonic Industry is also the market leader in EV relays. The range includes pre-charging and main relays, quick-charging relays and relays for normal charging, as well as high-voltage relays for accessories such as lighting and infotainment systems.

The relays control the electrical voltage. One of their most important functions is to interrupt the power supply with a special contact technology if the DC voltage is too high, in order to prevent heat damage and minimize safety risks, for example.

Relays in charging stations

As a central safety and switching element, relays from Panasonic Industry are also installed in charging stations, for example to de-energize charging technology. The relays are installed in charging devices of all sizes, whether for e-bikes, scooters and cars or for buses, trucks and forklifts.

An example is the HE-R, a high efficiency 40A relay for 3-phase systems. Panasonic has developed it specifically for AC charging stations based on the 3 to 22 kW operating mode. The HE-R, which has been on the market since 2021, is the world’s first PCB relay that can be used as the main switching element in three-phase systems. It is very compact and thus saves valuable space on the circuit board and thus also costs.

“The technological advance of the HE-R makes it possible to implement three-phase systems with just one relay directly on the printed circuit board,” summarizes Bernd Jaschinski from Panasonic Industry in Ottobrunn, Upper Bavaria. “This is not only interesting for the wall box in the garage and in the carport, but also for AC or DC charging stations and completely different areas of application such as industrial automation or energy harvesting.”

Panasonic Industry has once again proven its leadership in innovation and technology and is doing the same with future topics.

Read this and other articles on the subject of mobility 4.0 electrically-connected-autonomously in the current issue of the eMove360° magazine in german language for free download or as a print version available in the shop.