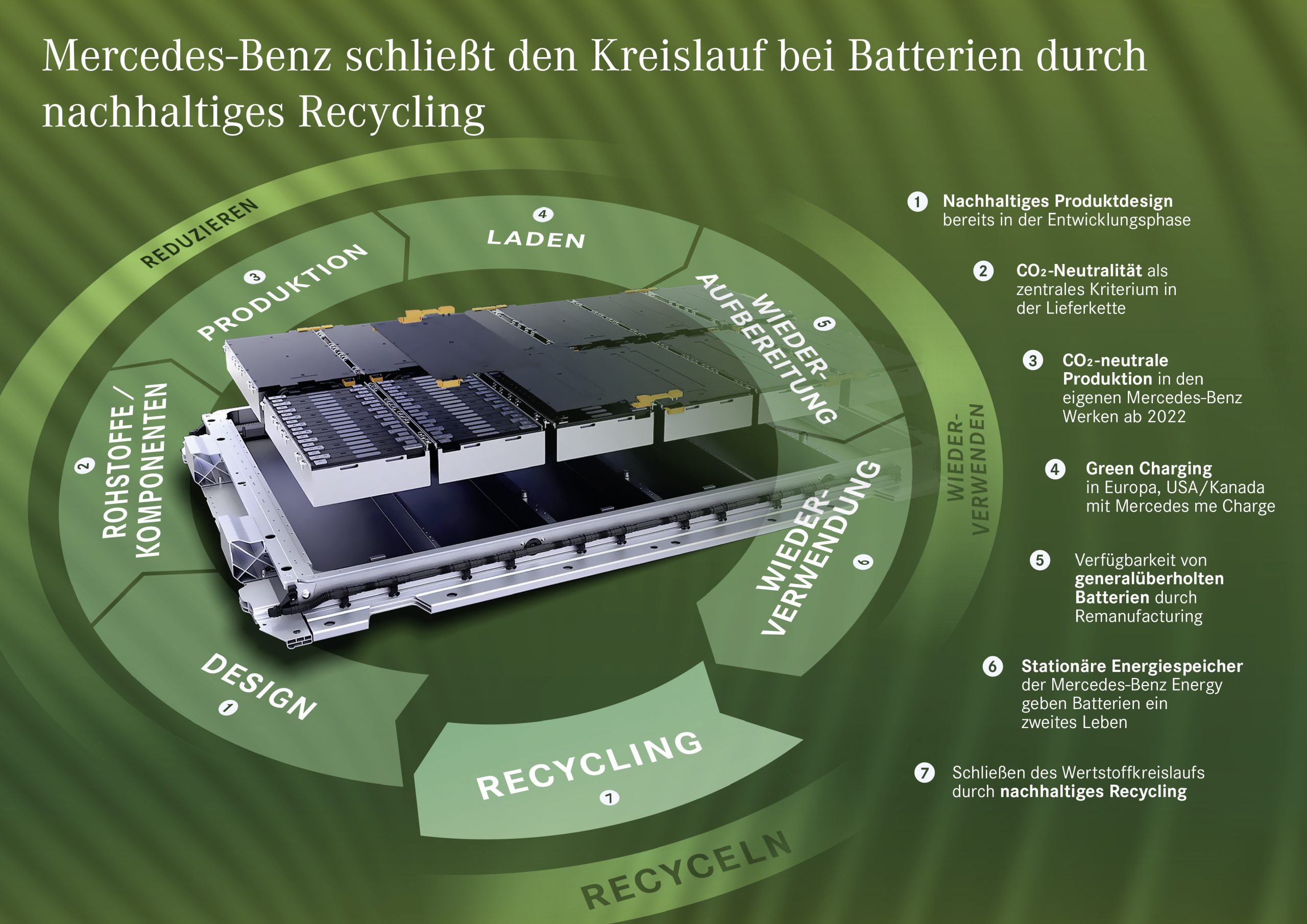

Mercedes-Benz schließt den Kreislauf bei Batterien durch nachhaltiges Recycling: Das Unternehmen hat das Prinzip der Nachhaltigkeit als festen Bestandteil in der Unternehmensstrategie verankert. Neben einer CO2-neutralen Produktion und der Umstellung auf ein vollelektrisches Fahrzeugportfolio ist dabei auch ein geschlossener Wertstoffkreislauf zur Reduzierung des Ressourcenverbrauchs entscheidend. Neben dem zirkulären Design und der Werterhaltung liegt der Fokus von Mercedes-Benz ebenso auf dem Recycling.

Mercedes-Benz schließt den Kreislauf bei Batterien durch nachhaltiges Recycling: Das Unternehmen hat das Prinzip der Nachhaltigkeit als festen Bestandteil in der Unternehmensstrategie verankert. Neben einer CO2-neutralen Produktion und der Umstellung auf ein vollelektrisches Fahrzeugportfolio ist dabei auch ein geschlossener Wertstoffkreislauf zur Reduzierung des Ressourcenverbrauchs entscheidend. Neben dem zirkulären Design und der Werterhaltung liegt der Fokus von Mercedes-Benz ebenso auf dem Recycling.

Mercedes-Benz schließt den Kreislauf bei Batterien durch nachhaltiges Recycling: Das Unternehmen hat das Prinzip der Nachhaltigkeit als festen Bestandteil in der Unternehmensstrategie verankert. Neben einer CO2-neutralen Produktion und der Umstellung auf ein vollelektrisches Fahrzeugportfolio ist dabei auch ein geschlossener Wertstoffkreislauf zur Reduzierung des Ressourcenverbrauchs entscheidend. Neben dem zirkulären Design und der Werterhaltung liegt der Fokus von Mercedes-Benz ebenso auf dem Recycling.

Mercedes-Benz schließt den Kreislauf bei Batterien durch nachhaltiges Recycling: Das Unternehmen hat das Prinzip der Nachhaltigkeit als festen Bestandteil in der Unternehmensstrategie verankert. Neben einer CO2-neutralen Produktion und der Umstellung auf ein vollelektrisches Fahrzeugportfolio ist dabei auch ein geschlossener Wertstoffkreislauf zur Reduzierung des Ressourcenverbrauchs entscheidend. Neben dem zirkulären Design und der Werterhaltung liegt der Fokus von Mercedes-Benz ebenso auf dem Recycling.

An important milestone in the global Mercedes-Benz battery recycling strategy is the establishment of its own pilot factory for recycling lithium-ion battery systems. To this end, Mercedes-Benz has founded Licular GmbH as a wholly owned subsidiary. Licular GmbH plans to cooperate with technology partner Primobius for the conceptual design and construction of the plant. Primobius is a joint venture between the German mechanical engineering company SMS group and the Australian project developer Neometals, and will contribute the necessary technological know-how, including the relevant preliminary studies, to the project. The companies have signed a letter of intent to this effect. Scientific support for the project will be provided by the renowned research institutes of the Karlsruhe Institute of Technology and the Technical Universities of Clausthal and Berlin.

The project is intended to set new standards in battery recycling from an ecological point of view: The process design of the patented hydrometallurgy with recovery rates of more than 96 percent is intended to enable a holistic recycling economy of battery materials. Mercedes-Benz is investing a double-digit million sum in research and development as well as the construction of the CO2-neutral pilot factory at the Mercedes-Benz Kuppenheim plant in southern Germany. The project has been promised funding under the Battery Innovation Support Program of the German Federal Ministry of Economics and Climate Protection.

In the future, the new pilot factory will map the entire process chain of battery recycling: from the development of logistics concepts and the sustainable recycling of valuable raw materials to the reintegration of recyclate into the production of new batteries. The basis of the new recycling plant is an innovative mechanical-hydrometallurgical process, which completely dispenses with energy-intensive and material-consuming pyrometallurgical process steps. The direct integration of hydrometallurgy into the overall concept of a recycling plant is a first in Europe and acts as a core element in the realization of sustainable battery recycling in the sense of a true circular economy. You can read more details about the structure of the plant and the holistic approach to battery value creation in the eMove360° magazine in german language starting on page 46.