Veganes Interieur ab 2023. Foto: BMW GROUP

Veganes Interieur ab 2023. Foto: BMW GROUP

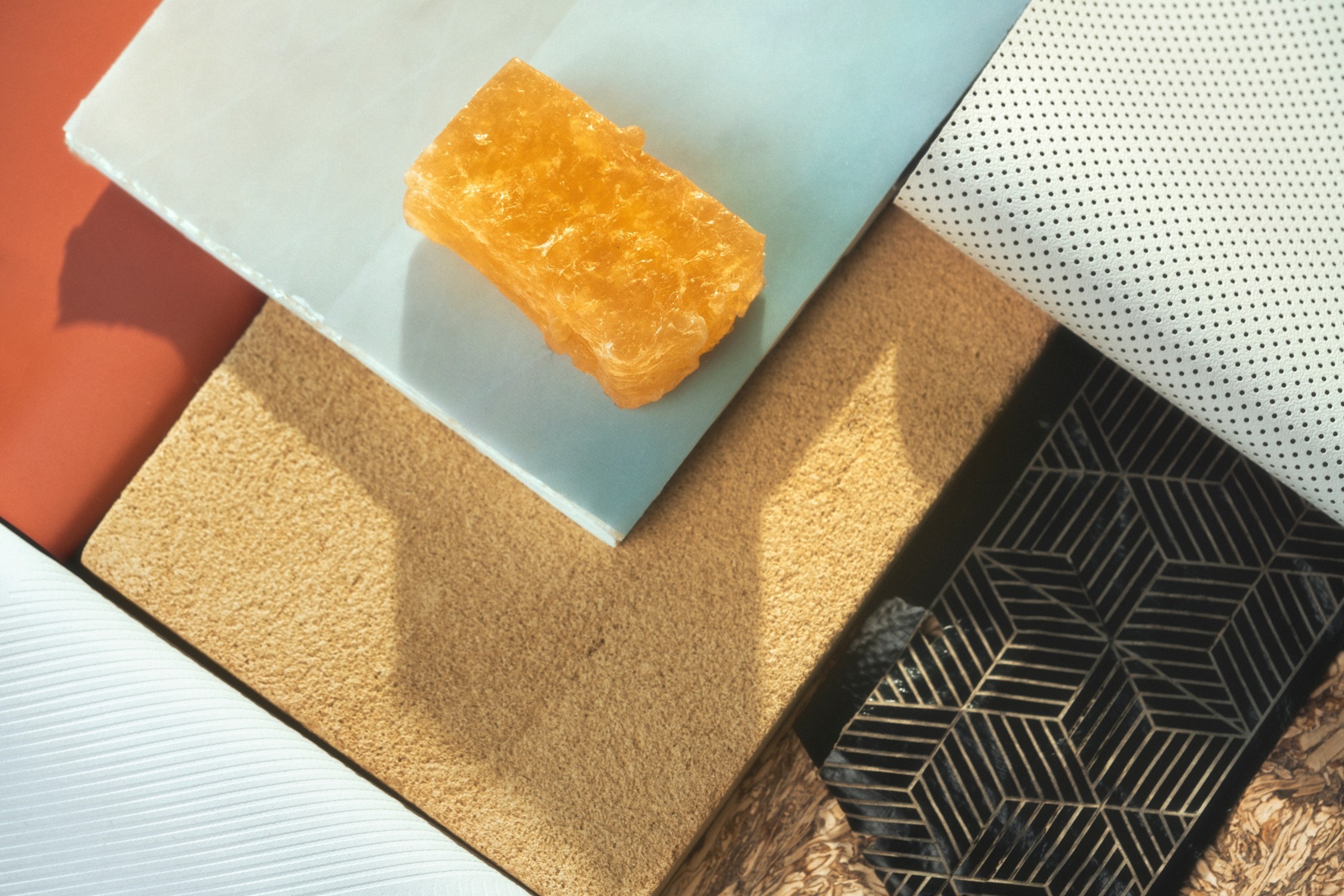

In 2023, the BMW Group will launch the first vehicles with completely vegan interiors. This will be made possible primarily through the development of innovative materials with leather-like properties. In the future, these can also be used for the surfaces of steering wheels, where they must meet particularly high requirements in terms of feel, premium appearance and wear resistance. Fully vegan interior variants will be available for the first time for both BMW and MINI models from 2023 onwards. In this way, the BMW Group is meeting the demand for vegan and leather-free trims, which is set to increase in the near future, particularly in the USA, China and Europe.

Leather-free surfaces reduce CO2e emissions by 85 per cent

The fact that now also in the production of steering wheels a high-quality vegan surface material with qualitatively equivalent properties can replace the genuine leather used so far, enables another big step towards CO2 reduction. By using the new material for steering wheel surfaces, around 85 percent of CO2 emissions are saved along the value chain compared to leather. Up to now, most of the emissions (around 80 percent) have been in the form of methane gas from cattle rearing. The remaining 20 percent were caused by the energy- and water-intensive processing of cattle skin.

Climate neutrality and circular economy

On its way to achieving climate neutrality, the BMW Group relies on the use of green electricity in production and in the supply chain, a consistently increased share of secondary materials and natural raw materials, highly efficient electric and combustion engines, and a high recycling rate in the sense of a circular economy.

In this context, details matter: For example, the floor mats for numerous models are made of so-called mono-material. This avoids a mix of materials that is difficult to recycle. As a result, the BMW Group saves around 23,000 tonnes of CO2 per year and an additional 1,600 tonnes of waste, as the recycled floor mats and material offcuts are reused within the production process.

Research and development in the field of secondary raw materials and sustainable materials have top priority. Future vehicle generations will have more attractive alternatives to leather. The BMW Group is developing innovative bio-based surfaces in cooperation with start-up companies. Compared to the leather replicas used to date, this is associated with a further reduction in CO2 emissions of around 45 per cent. For example, the 100 percent bio-based and petroleum-free MirumTM offers the potential to imitate all the traditional properties of leather in the future. DeserttexTM, also newly developed, is composed of powdered cactus fibres and a bio-based polyurethane matrix. With these materials, the renunciation of raw materials of animal origin can be combined with a significant reduction in CO2. www.bmwgroup.com