Rheinmetall Automotive, a first-tier auto-industry supplier and member of the Technology Group Rheinmetall AG, is taking account of the increasing electrification of cars and commercial vehicle drivelines in its own product range.

Reflecting the trend, at this year’s International Motor Show (IAA) in Frankfurt, the Company will include among its exhibits a newly developed 90 kW electric drive unit as well as a new kind of modular battery pack. The systems are currently installed in a demonstration vehicle built around a sub-compact car.

The 90-kW high-voltage motor from Rheinmetall Automotive can be adapted to the respective application in terms of output and torque characteristics. The current design is tailored to smaller-sized vehicles. However, the system’s scalability allows it to be used in larger vehicles, too. Here, Rheinmetall Automotive has opted for a synchronous permanent-magnet motor. And to allow for the restricted installation space, it was decided to use a concentrated coil.

The motor is built into a subcompact demonstration vehicle with a battery pack rated at 29 kWh. With the new electric drive, the vehicle has a top speed of 135 km/h and a range of up to 275 km. These specifications are achieved without encroaching on the luggage compartment space or the passenger compartment normally available on the series version of this vehicle.

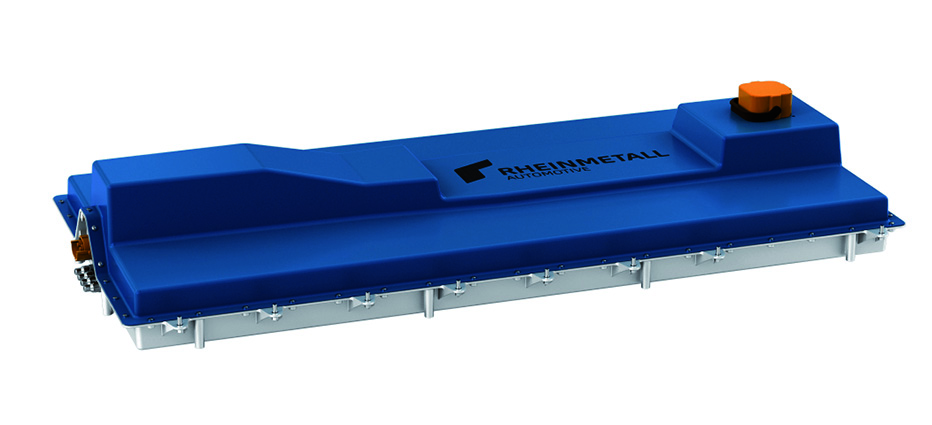

In the design of the new battery pack, Rheinmetall Automotive has worked from the premise that future electric vehicles and hybrids will largely use underfloor batteries which do not diminish the vehicle’s loading capacity to any major degree while offering advantages in terms of weight distribution and integration into the vehicle’s structure.

The basic structure of the modular battery pack is made from aluminum into which customer-specific battery modules can be integrated. This arrangement is remarkable for its high energy density in relation to weight and, thanks to its compact dimensions, permits flexible and wide-ranging use in electric vehicles.

The battery packs have their own cooling system and are shielded from intrusion by a composite-fiber structure developed by an affiliate within the Rheinmetall Group specializing in protection systems.

The Company perceives this configuration tailored to future electric vehicles as a possible series-production project yet allowing other arrangements to be assembled in order to address customer wishes.

Rheinmetall Automotive possesses decades of engineering expertise in electric drive systems for auxiliary components. Back in 2004 and through its Pierburg subsidiary, it had developed the first all-electric coolant pump for the main cooling system which was then successfully launched in the six-cylinder BMW engines.

www.rheinmetall-automotive.com