Webasto convinced the jury of experts of the eMove360° Award for electromobility & autonomous driving with a modular standard battery system for commercial vehicles that combines the price advantages of a scalable plug-and-play mass product with the accuracy of a customer-specific solution.

Durable standard battery systems for commercial vehicles

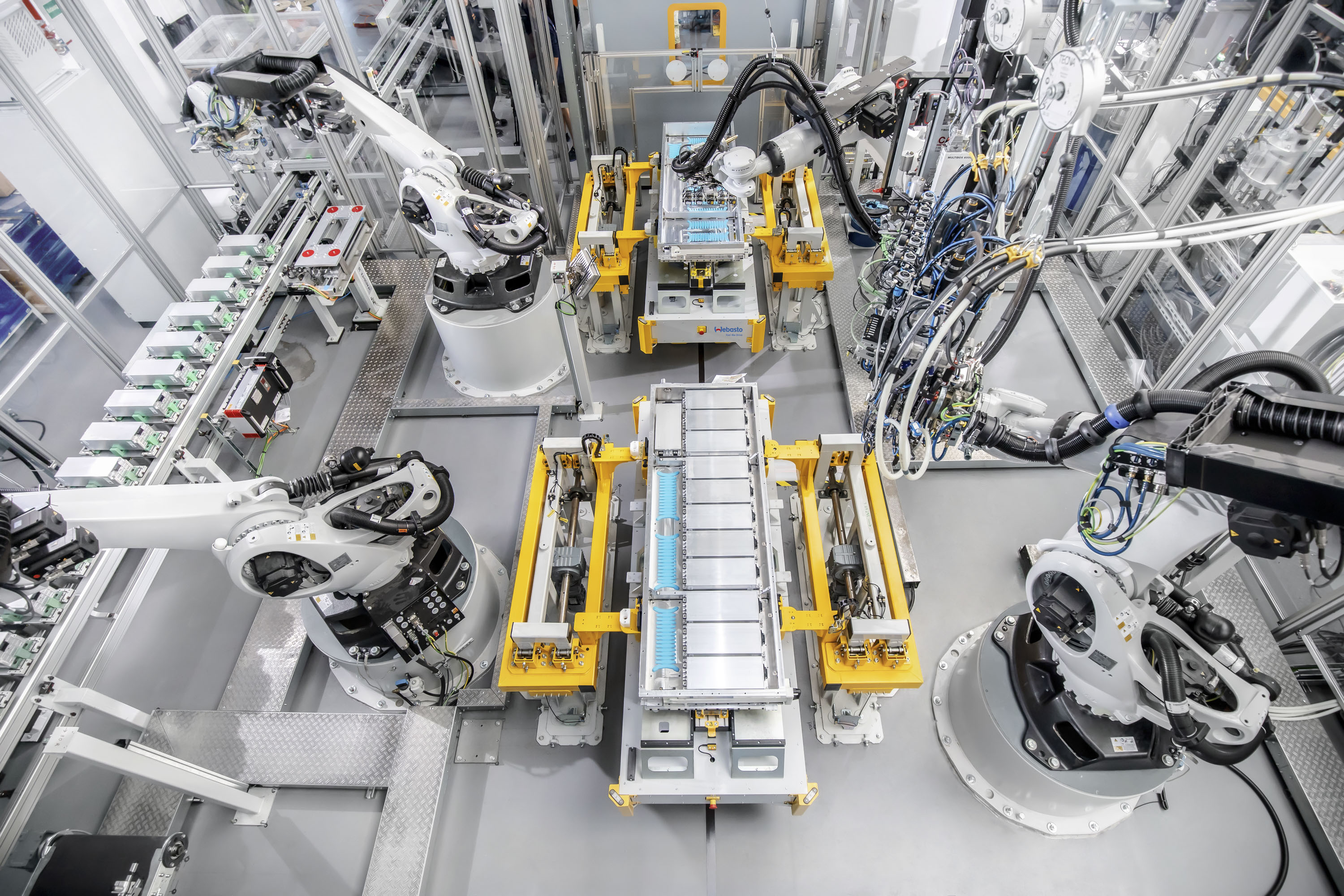

The modular standard battery system for commercial vehicles combines the price advantages of a scalable plug-and-play mass product with the accurate fit of a customized solution. With a system configuration of between 400 and 800 V and up to 350 kWh, the scalable solution is suitable for all types of commercial vehicle. The latest generation of high-quality, fully tested battery cells ensures exceptionally long service life – also thanks to liquid cooling, integrated thermal management and a robust housing. Low development costs combined with efficient mass production, outstanding product life and low unit prices result in a convincing TCO. Manufacturing in Europe ensures efficient supply chains. The Vehicle Interface Box (VIB) provides a single interface for communication between the battery system and the vehicle, allowing up to ten battery systems to be controlled within a system. Furthermore, the VIB ensures efficient electrical connection of the battery systems and allows connection of auxiliary units.

Clean mobility with the highest quality standards

Webasto’s standardized and individualized battery systems meet the highest quality, safety and performance requirements. The robust housing has a unique design. At own test and prototype center Webasto conduct extensive corrosion, leakage and thermal shock tests and continually validate both cells and battery systems. The center has the capacity for building up to 1,200 battery system prototypes per year, which means they guarantee rapid internal setup and therefore short development cycles. Their competencies include internal mechanical system development and integration, leading-edge thermal management, internal software and algorithm development, and the design and production of all E/E components. In the production facility, you can flexibly manufacture a wide range of batteries up to 40,000 pieces per year. For a green future, Webasto considers the entire product cycle and is looking for ways to reduce his carbon footprint still further: Together with specialized recycling companies, Webasto is developing concepts for reusing battery systems.

www.webasto.com/de