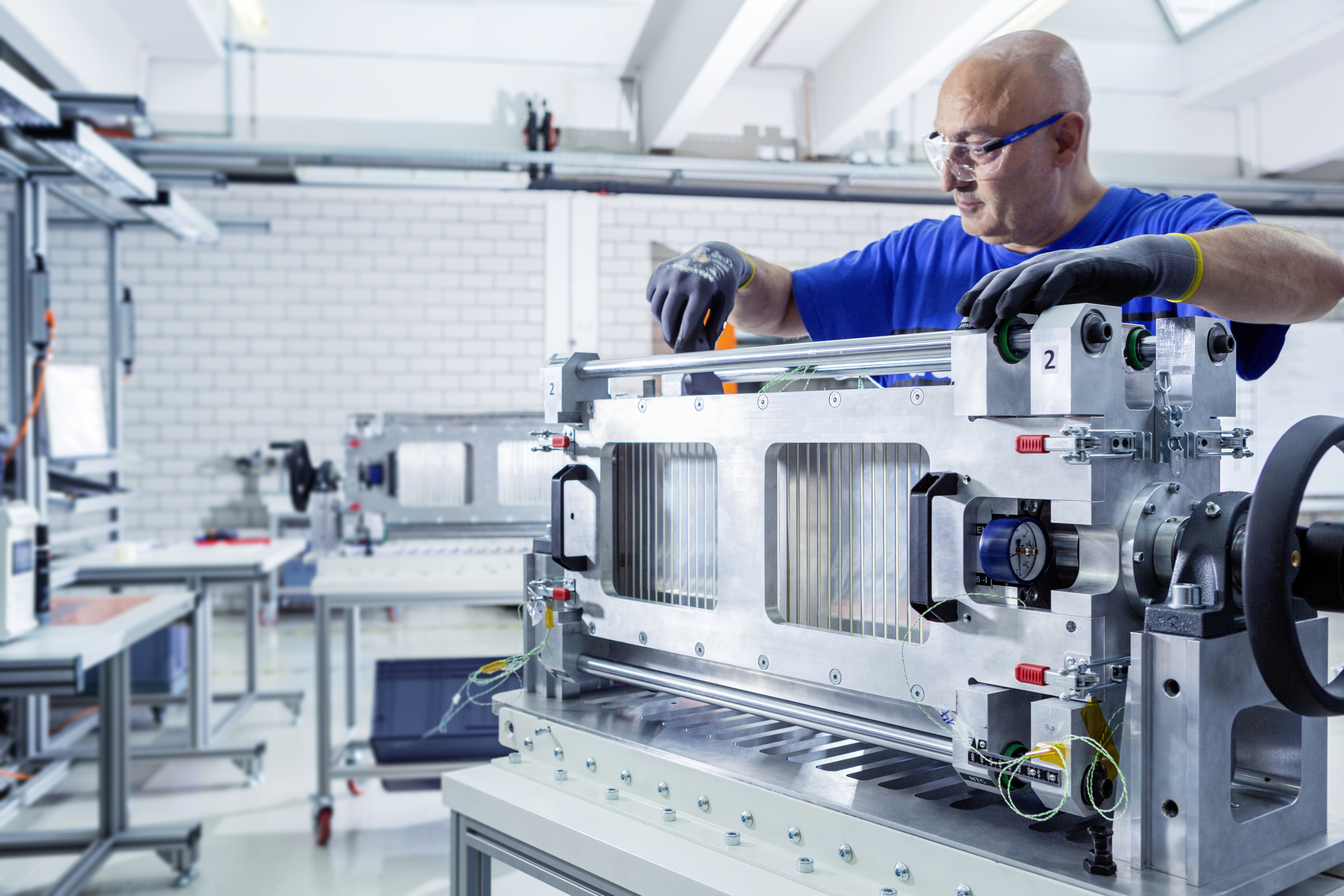

Farasis Produktion. Foto: Farasis Energy/Arne Hartenburg

Farasis Produktion. Foto: Farasis Energy/Arne Hartenburg

Direct recycling of lithium-ion batteries is a recycling process that preserves the crystal structure of the cathode material, which enables cost- and energy-saving reuse of the material. Farasis Energy has been able to demonstrate that recycled cathode material can be recovered from used cells or production scrap and incorporated into new cells. Specifically, it has been demonstrated that cells containing up to 25 percent recycled cathode material can provide equivalent performance to cells made exclusively from virgin cathode material. The direct recycling process thus makes it possible to significantly reduce the use and amount of virgin, active cathode material without compromising the performance of the newly manufactured batteries. At the same time, it contributes to a more environmentally friendly and sustainable method of cell production and reduces the overall carbon footprint. “Our goal is to develop a closed-loop battery value chain throughout its lifecycle, from design to end-of-life management,” said Dr. Keith Kepler, CTO and co-founder of Farasis. “We have made significant progress toward this goal with the validation of our direct recycling process.” Read more details in the current issue of eMove360° magazine in german language – download for free or order in the shop.