©Cision

©Cision

Mining company Eurobattery Minerals AB has received the first results of its research collaboration with Uppsala University in collaboration with AGH University of Science and Technology in Krakow, Poland. The results describe new methods for large-scale extraction of rare earth elements (SEE – rare earth elements or rare earth metals) at its Fetsjön project in Sweden. SEE are critical raw materials for the battery industry and new energy solutions. With nearly 100 percent imports outside the EU, the European Union has set a goal to increase its self-sufficiency.

Key points: Newly developed and tested breakthrough method enables nearly 100 percent recovery of SEE from the apatite minerals of Fetsjön and adjacent Rönnberget. Previous analysis of the total SEE-bearing shale formation comprising Eurobattery Minerals’ Fetsjön and Rönnberget exploration targets is estimated at 165,000 to 180,000 tonnes of SEE. The magnitude of the exploration target has been confirmed in a NI43-101 technical report by a qualified person. SEE can be recovered by chemical treatment at low temperatures, avoiding costly and time-consuming mechanical treatment. Low temperature treatment allows the chemicals to be used in a circular fashion. Next step: further testing to characterize the SEE-bearing minerals in detail, and possibly a full-scale pilot plant in the near future.

“These are very exciting results from our joint research project. Based on previous analyses, we know that our Fetsjön project and the adjacent Rönnberget contain large amounts of SEE. These initial results show that we have a very significant SEE deposit, with a recovery rate close to 100%, where we could apply a revolutionary new recovery method,” said Roberto García Martínez, CEO of Eurobattery Minerals.

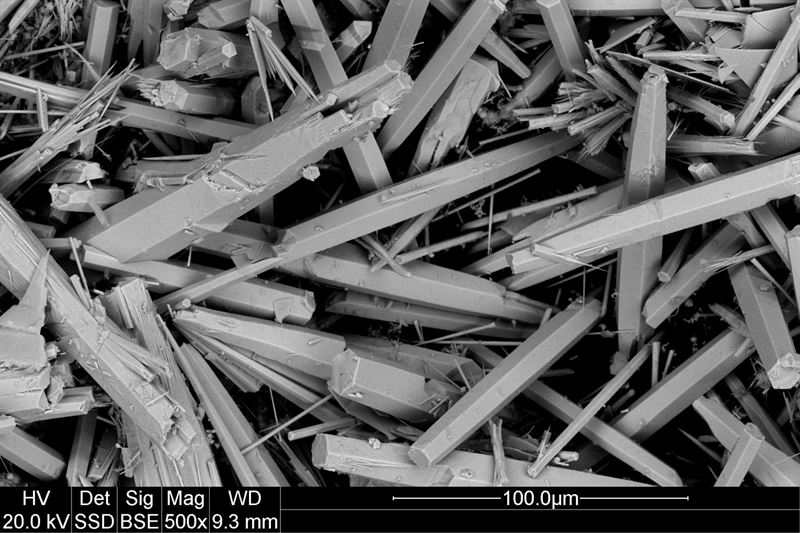

Using drill core samples from Eurobattery Minerals’ Fetsjön prospect area in northern Sweden, scientists conducted a detailed mineralogical and geochemical study of the shales and identified the SEE containing minerals – mainly apatite. The composition of the Fetsjön carbonate-apatite shale makes it particularly suitable for rare earth leaching using modern methods, according to the scientists.

The Uppsala-Krakow team has developed a new, cost-effective and efficient method for processing SEE from apatites and similar mineralization to recover up to 100% of the SEE from the Fetsjön deposits, which contain apatites, carbonate minerals and other SEE carriers. In addition, the identified process is very efficient both from a cost and time point of view, as it allows the recovery of rare earths only through low temperature chemical treatment, thus avoiding the step of mechanical pretreatment and heating. In addition, the low-temperature treatment means that the chemical can be recycled and reused.

“SEEs are made up of scandium, yttrium and the lanthanides that are critical to electrification, so there is a great need for raw materials. However, the extraction of SEE, especially from apatites, is often very difficult. Therefore, I am pleased with the preliminary results of our project, which show that our new approach can achieve high concentrations just by chemically treating the carbonate apatite rock,” said Prof. Jaroslaw Majka of Uppsala University.

The EU classifies rare earths as critical raw materials; today, the region is almost 100% dependent on imports. The EU is therefore pushing for greater European extraction of SEE. “In this context, Eurobattery Minerals, its project at Fetsjön and the research collaboration play an important role in increasing Europe’s self-sufficiency in responsibly mined battery minerals,” said Roberto García Martínez.

The project will now continue with additional testing for detailed characterization. The parties are also exploring the possibility of a full-scale pilot plant in the near future. The research project is led by Prof. Jaroslaw Majka at Uppsala University and Prof. Maciej Manecki at AGH University of Science and Technology in Krakow, assisted by Ph.D. candidate Julia Sordyl representing both universities. https://eurobatteryminerals.com

http://news.cision.com/de